#Automatic soldering Robot

Explore tagged Tumblr posts

Text

ok so puppyboys that are anthro furries or "human" are standard, but we need to also consider puppyboys that are robots. robots that are good puppies. because. imagine for a moment affixing a shock collar to a robot's neck, metal to metal... or maybe even wiring it directly into the robot's circuitry... you get the idea. fuuuck you wouldn't even need to clicker train it, you could just program it to automatically respond to clicks the way you want. not to mention modifying a non-puppy robotic body to be more puppylike in nature... soldering a tail onto them ... you understand. robot fuckers you are my siblings in arms in this battle.

22 notes

·

View notes

Text

EXPLORING THE 5 COOL PARTNER SELLER ELECTRONICS PRODUCTS-Part1

Exploring the 5 Cool Partner Seller Electronics Products

Prologue

Are you an electronics enthusiast looking to expand your electronics project repertoire? Want to take your skills to the next level by exploring new and exciting products? Look no further than our list of five cool electronics products from partner sellers!

Whether you’re interested in building your own smart home devices, experimenting with sensors, or creating your own robot, these products are sure to inspire you. They cover a lot of application areas, from loop detectors used to monitor vehicle count in parking garages to Arduino CNC shields used in CNC machines, from simple pulse sensors used to detect cardiovascular pulse signals from fingertip to RGB LED panel light used in smart home, these products are unique, compact, and functional. Not only are these products fun to build and use but they’re also designed to help you learn new skills and techniques along the way.

What’s more, these products all come from trusted partner sellers who are committed to developing high-quality products. They’re happy to provide technical support for customers who have questions, so you can be sure you’re getting the best in electronics.

So get ready to dive into the world of electronics and explore these five cool partner seller products. You’re sure to find something that piques your interest and takes your own electronics projects to the next level.

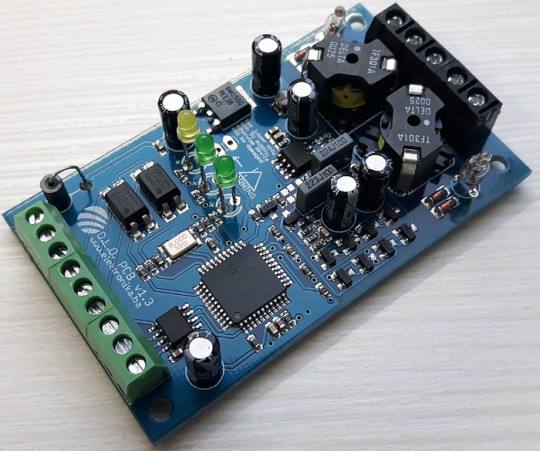

Inductive Loop Vehicle Detector by Elektronika-ba

Whether you need to monitor occupancy and count vehicles in parking garages, control vehicle access at door and barrier controls, or facilitate traffic light installations and traffic controllers, the inductive loop detector is the perfect solution. It can even detect the direction and speed of vehicle traffic, making it an invaluable tool for a variety of traffic-related applications. In addition, this device can function as a stand-alone speed trap and can be easily interfaced with Arduino.

We can also provide a pre-programmed PIC chip to meet your project requirements.

Specifications

Number of operating modes: 4

Tuning: Automatic

Detection type: Presence/Pulse

Presence time: Adjustable in 3 steps

Pulse duration: 250 ms / 500 ms

Signal filtering: Adjustable in 2 steps (NORMAL, HIGH)

Loop inductance: 20 uH — 1000 uH

Frequency range: 20 kHz — 145 kHz

Frequency selection: 2 combinations (LOW, HIGH)

Sensitivity: Maximum 0.0025% Δf/f, adjustable in 8 steps

Detection speed: 10 ms by default, adjustable

Start-up time: ~ 1 second per channel (or longer if the frequency is not stable)

Temperature range: -35°C — 120°C

Sensor protection: Galvanic isolation + gas discharge tube for lightning protection

Don’t settle for less — click here to learn more about the Inductive Loop Vehicle Detector and experience the compact, yet cool detector!

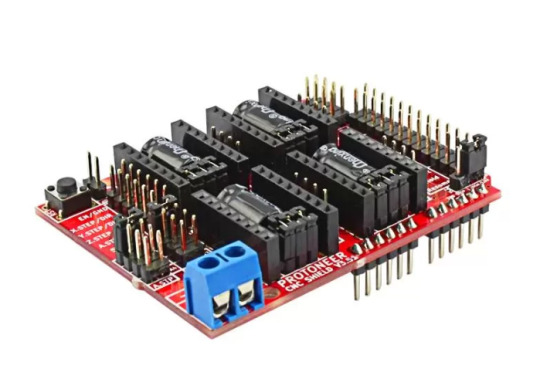

Arduino CNC Shield V3.51 by Protoneer

Designed by Protoneer, this kit is packed with features to ensure high precision control of your stepper motors, you can use it to easily build small CNC routers, DIY laser cutters, 3D printers, or any project that requires precise stepper motor control.

Our latest version 3.51 includes several enhancements to make assembly and installation even easier. We’ve added end-stop and probe signal filtering circuitry to eliminate false triggers and allow the use of unshielded cables for end-stops and probes. We’ve also increased the size of the solder pads for easier assembly and updated the probe pin labels to make installation a breeze.

With the Arduino CNC Shield Kit, you’ll have everything you need to build your own CNC router or mill with ease.

Features

Includes Noise Filers on all end stops and the probing pin. (New in V3.51)

GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

4-Axis support (X, Y, Z, A-Can duplicate X, Y, Z or do a full 4th axis with custom firmware using pins A4 and A3)

2 x End stops for each axis (6 in total)

Coolant enable

Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others)(Not Included)

Jumpers to set the Micro-Stepping for the stepper drivers. (Some drivers like the DRV8825 can do up to 1/32 micro-stepping )

Compact design.

Stepper Motors can be connected with 4-pin molex connectors or soldered in place.

Runs on 12–36V DC. (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.)

Don’t wait — click here to see more about the Arduino CNC Shield V3.51 and start your next project today!

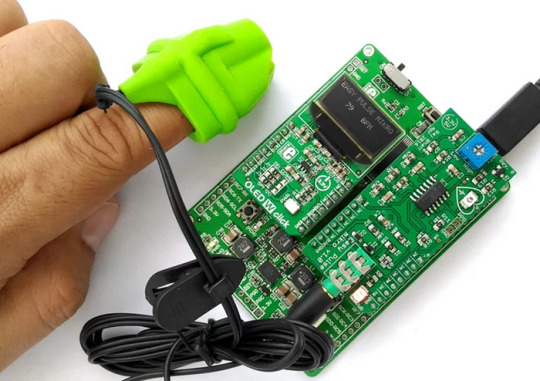

Easy Pulse Mikro by Embedded Lab

What’s more, the Easy Pulse Mikro is designed in the convenient Mikro bus form factor, making it easy to integrate with a wide range of mikroElektronika’s development boards. With all necessary instrumentation and amplification built right in, this powerful sensor provides a clean and precise analog PPG waveform output that’s routed to the AN pin of the mikroBus connector.

Whether you’re a hobbyist, student, or professional developer, the Easy Pulse mikro is the perfect tool for monitoring heart rate and other vital signs.

Click here to see more about the Easy Pulse mikro.

Features

Compatible with mikroBus socket.

Filtered and amplified analog PPG signal output

On-board potentiometer for adjusting amplifier gain, if needed (rotate clock-wise for increasing gain)

Onboard LED for indicating heartbeat. It flashes synchronously with the heartbeat on detecting the pulse from the fingertip.

2 notes

·

View notes

Text

Top Trends in PCB Assembly for 2025

PCBs are the heart of the modern world. Whether it’s household equipment, industrial equipment, or defense ordnance, printed circuit boards are running everything. With new developments, the global scene of PCB manufacturing is changing rapidly. Using the newest technologies is not only a great concept, but staying competitive depends on it as well. From downsizing to AI-driven manufacturing, 2025 promises to bring major breakthroughs along with making advancements in current technologies that will change the way Printed Circuit Boards (PCBs) are manufactured.

This article will walk you through some key industry trends that will sketch the future of PCB assembly.

5 Key Trends in PCB Assembly to Follow in 2025

As the world is moving towards manufacturing more complex products and adopting advanced technologies, the PCB assembly industry is also observing several key trends. Here are a few noteworthy trends to follow.

1. Shrinking is in High-Density Interconnections: HDI and Miniaturization

Think about our daily gadgets, such as wearables, Internet of Things devices, and sophisticated medical electronics. These devices need robust and small PCBs, and therefore, in these spaces, High-Density Interconnect (HDI) technology excels. HDI lets electronic gadgets be more powerful despite their compact stature. In what manner? For high-speed applications, it increases signal integrity, lowers component spacing, and permits smaller trace lengths, hence enhancing electrical performance. And it will change the entire PCB manufacturing market.

According to a forecast [1], the HDI PCB market is expected to rise rapidly and, by 2032, will reach almost $40 billion. That makes the direction in which things are heading quite obvious.

2. Smart Factories: Artificial Intelligence and Automation

Like in every other industry, PCB assembly is becoming significantly faster, smarter, and more efficient. Industry 4.0 and manufacturing driven by artificial intelligence lead the push. Think about robotic soldering and pick-and-place robots for fast, more perfect component installation. Artificial intelligence and machine learning have found their way into quality control, that is, for error reduction and flaw detection done automatically. Imagine the Internet of Things, connected production lines, allowing real-time monitoring and predictive maintenance.

3. Bendable and Adaptable: Rigid-flexible PCBs

Flexible and rigid-flex printed circuit boards are becoming more popular in industries such as transportation, aircraft, and healthcare electronics. But you may think, why so? Because of their small size and lightweight nature, they are ideal for manufacturing small, portable electronic devices. They can withstand significant external force and resist bending and vibration. They endure longer with fewer interconnect failures, making them more reliable.

4. Green is Good: Manufacturing Sustainable Circuit Boards

Growing worries about e-waste and carbon footprints force sustainability to the front stage in PCB production. Lead-free soldering, biodegradable and reusable substrates, recyclable materials, and energy-efficient manufacturing procedures will become the focal points in the near future. It’s about matching global laws and customer demand as much as it is about environmental responsibility.

5. Printing the Future: 3D Printing in PCB Assembly

Additive manufacturing is revolutionizing PCB manufacturing and streamlining complex multilayer design construction. From this, faster prototyping, reduced material waste, and more customization for specific uses follow. This is a breakthrough for design and development; it will only get more so.

The Final Thought

There are a lot of exciting new possibilities in the PCB assemblyand PCB manufacturing industries. Miniaturization, automation, sustainability, and developments in AI-driven manufacturing will enable you to produce premium printed circuit boards (PCRs) that satisfy future electronics needs. Survival in a dynamic industry depends on keeping ahead of the competitors. By following these trends and wise technology investments, you could set yourself up for success in 2025 and beyond.

Know More : https://www.pcbpower.us/blog/top-trends-pcb-assembly

0 notes

Text

The Role of Automatic Soldering

Enhancing Operational Efficiency in Electronics Manufacturing: The Role of Automatic Soldering In today’s rapidly evolving manufacturing landscape, where precision, speed, and reliability are non-negotiable, automatic soldering has emerged as a game-changing solution. Particularly in the electronics and electrical sectors, where component miniaturization and high-density boards are the norms, traditional soldering methods often fall short. Automatic soldering technology bridges this gap—delivering consistent results, reducing human error, and enhancing overall productivity.

What Is Automatic Soldering? Automatic soldering refers to the use of machines and robotic systems to perform soldering tasks that were traditionally done manually. These systems are designed to apply solder precisely and efficiently, whether through wave soldering, selective soldering, or robotic point soldering. Unlike manual methods, which are labor-intensive and vary based on technician skill, automatic soldering ensures high repeatability and precision, making it ideal for large-scale production lines and quality-driven industries.

Why Automatic Soldering Matters 1. Consistent Quality and Precision Automatic soldering systems follow exact parameters for temperature, timing, and positioning. This eliminates the inconsistencies found in manual soldering and ensures robust solder joints, which are critical for long-term device performance.

2. Increased Throughput In fast-paced industries like consumer and automotive electronics, saving time means saving money. Automatic soldering machines can work faster and more accurately than human operators, drastically increasing production speeds without compromising quality.

3. Reduced Labor Costs By automating repetitive tasks, manufacturers can significantly reduce reliance on manual labor, reassign skilled technicians to more complex duties, and lower operationalcosts over time.

4. Enhanced Safety Soldering involves high temperatures and potentially hazardous fumes. Automation minimizes human exposure to these risks, promoting a safer workplace environment. Applications of Automatic Soldering Across Industries Electronics Manufacturing Used extensively for PCB assembly, automatic soldering ensures tight quality control for devices ranging from smartphones to industrial controllers.

Automotive Sector As electric cars and driver-assistance systems become more common, car electronics need accurate and dependable soldering. Automatic systems help make sure these important safety parts stay reliable.

Telecommunication Equipment Devices used in communication networks have tightly packed circuit boards. Automated soldering is essential for creating reliable connections, especially in complex or hard-to-reach areas.

Medical Devices In an industry where precision can be life-saving, automated soldering offers the accuracy needed for implantable devices, diagnostic machines, and other sensitive equipment.

Choosing the Right Automatic Soldering Solution

When selecting an automatic soldering system, manufacturers should consider:

Type of Soldering Method: Wave, selective, or robotic soldering, based on product complexity.

Component Sensitivity: Ensure compatibility with heat-sensitive components.

Production Volume: Choose equipment that can handle your expected throughput.

Flexibility: Systems that adapt to varying board layouts are a plus in dynamic manufacturing settings.

The Sumitron Advantage in Soldering Solutions As more industries embrace automation, trusted partners like Sumitron provide more than just tools—they deliver integrated solutions. From ESD-safe soldering stations to robotic soldering systems, Sumitron offers a curated range of products to meet the exacting needs of today’s electronics manufacturers. With a deep understanding of industry requirements and a commitment to quality, Sumitron ensures every solution is tailored to maximize uptime, reduce errors, and future-proof your production line.

Looking Ahead: The Future of Soldering is Smart The future of automatic soldering is being shaped by Industry 4.0, with intelligent machines capable of real-time monitoring, predictive maintenance, and self-adjusting soldering profiles. As AI and IoT converge with manufacturing, automatic soldering systems will not only perform tasks—but also optimize and evolve with production needs.

Conclusion: Whether you're producing cutting-edge electronics or mission-critical automotive components, automatic soldering is no longer a luxury—it’s a necessity. With benefits that touch every aspect of manufacturing, from cost and quality to safety and speed, adopting this technology is a smart move for future-ready businesses.

Discover Sumitron’s range of soldering automation tools and elevate your production capabilities with solutions engineered for excellence.

1 note

·

View note

Text

Industry 4.0 Innovations Transforming Electronics Assembly

In today's rapidly evolving manufacturing landscape, electronics assembly operations are undergoing a profound transformation. The fourth industrial revolution, commonly known as Industry 4.0, has ushered in a new era of smart manufacturing that's reshaping how electronics components are assembled, tested, and brought to market. For manufacturers looking to stay competitive, understanding these innovations isn't just advantageous—it's essential for survival.

The Evolution of Electronics Assembly

Traditional electronics assembly relied heavily on manual processes and disconnected machinery. Operators would manually load components, monitor equipment, and make adjustments based on visual inspections. While this approach served the industry for decades, it came with significant limitations in speed, accuracy, and scalability.

Fast forward to today, and the picture looks dramatically different. Modern assembly lines feature interconnected systems that communicate in real-time, making autonomous decisions and adjustments without human intervention. This paradigm shift hasn't happened overnight—it's the result of several converging technologies that collectively define the Industry 4.0 movement.

Key Technologies Driving the Transformation

1. Internet of Things (IoT) Integration

The backbone of smart manufacturing lies in connected devices. IoT sensors embedded throughout the production line collect vast amounts of data on everything from component placement accuracy to environmental conditions.

Modern pick and place machines, for example, can now transmit real-time performance metrics to central management systems. This allows production managers to monitor the status of multiple machines simultaneously and identify potential issues before they escalate into costly downtime scenarios.

2. Artificial Intelligence and Machine Learning

Perhaps the most revolutionary aspect of Industry 4.0 is the implementation of AI and machine learning algorithms that can analyze production data and make intelligent decisions.

In surface mount technology applications, these systems can:

Predict when equipment maintenance will be required based on subtle changes in performance metrics

Automatically adjust placement parameters to optimize for different component types

Identify patterns in defects that might go unnoticed by human inspectors

Leading equipment manufacturers have integrated these capabilities into their latest models. The advanced pick and place machines now feature self-learning algorithms that continuously improve placement accuracy over time, reducing errors and minimizing waste.

3. Digital Twin Technology

Digital twin technology creates virtual replicas of physical equipment and production processes. These digital models simulate real-world conditions and allow engineers to test changes or optimizations without disrupting actual production.

For electronics manufacturers, this means being able to:

Simulate the introduction of new components to identify potential assembly challenges

Test different equipment configurations to maximize throughput

Train operators on new procedures in a risk-free virtual environment

4. Advanced Robotics and Cobots

While robotics has been part of electronics manufacturing for decades, Industry 4.0 has introduced more flexible, intelligent robotics systems. Collaborative robots (cobots) work alongside human operators, handling repetitive tasks while humans focus on more complex aspects of production.

In modern electronics assembly, these advanced robots handle everything from component placement to intricate soldering operations with precision that exceeds human capabilities. The latest generation of placement equipment can achieve placement accuracies measured in microns, essential for today's increasingly miniaturized electronics.

Real-World Implementation Success Stories

Companies that have embraced these technologies are reporting significant improvements across multiple performance metrics.

One electronics contract manufacturer reported a 37% decrease in defect rates after implementing AI-powered optical inspection systems integrated with their placement equipment. The system could identify subtle patterns in misplacements that were previously going undetected until final testing.

Another manufacturer specializing in consumer electronics achieved a 42% reduction in changeover times by implementing digital work instructions and automated setup verification on their assembly line. Their investment in advanced pick and place technology with automatic feeder verification eliminated manual setup errors that previously caused production delays.

The Critical Role of Equipment Selection

Achieving these benefits requires careful selection of manufacturing equipment capable of supporting Industry 4.0 functionality. When evaluating surface mount technology equipment, manufacturers should consider:

Connectivity Capabilities

Modern equipment should feature open communication protocols that allow seamless integration with manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms. Look for machines that offer standard communication interfaces and well-documented APIs.

Data Collection and Analysis

Advanced placement equipment now offers comprehensive data collection capabilities, tracking everything from placement accuracy to component usage patterns. The most advanced systems include built-in analytics that transform raw data into actionable insights.

Flexibility and Scalability

As production needs evolve, equipment should be able to adapt without requiring complete replacement. Modular design philosophies from leading manufacturers allow for easier upgrades and expansions as technology advances.

Implementation Challenges and Solutions

Despite the clear benefits, implementing Industry 4.0 technologies comes with challenges. Many manufacturers struggle with:

Legacy Equipment Integration

Not all manufacturers can afford to replace their entire production line with the latest equipment. Integration solutions that allow older placement machines to connect with newer systems are essential for practical implementation.

Skills Gap

Operating and maintaining advanced manufacturing technology requires specialized skills. Forward-thinking manufacturers are investing in comprehensive training programs and partnering with equipment suppliers that offer robust support services.

Data Security Concerns

As manufacturing systems become more connected, cybersecurity becomes increasingly important. Implementing proper security protocols is essential to protect both production data and intellectual property.

The Future of Electronics Assembly

Looking ahead, the integration of Industry 4.0 technologies in electronics assembly will only accelerate. We're seeing early adoption of technologies like augmented reality for maintenance procedures and increasingly autonomous production lines that can run with minimal human oversight.

For manufacturers, the message is clear: embracing these technologies isn't just about staying current—it's about survival in an increasingly competitive global market. The companies that thrive will be those that view Industry 4.0 not as a buzzword but as a fundamental shift in how electronics manufacturing operates.

By investing in modern assembly equipment, developing the necessary technical capabilities, and fostering a culture of continuous improvement, electronics manufacturers can position themselves to reap the substantial benefits of smart manufacturing well into the future.

Conclusion

Industry 4.0 represents the most significant transformation in electronics manufacturing since the introduction of automation. By connecting machines, leveraging data analytics, and implementing intelligent systems, manufacturers can achieve levels of efficiency, quality, and flexibility that were previously impossible.

As you evaluate your own operations, consider how these technologies might address your specific challenges and opportunities. The journey toward smart manufacturing is complex, but with careful planning and implementation, the benefits make it well worth the effort.

0 notes

Text

The Rise of Automatic BGA Machines in India: A Game Changer for Electronics Manufacturing

As the demand for high-performance electronics continues to soar, manufacturers are constantly seeking innovative solutions to streamline production and enhance product quality. In the world of Surface Mount Technology (SMT), Ball Grid Array (BGA) components have become increasingly common due to their superior performance and miniaturization capabilities. To handle the delicate process of placing and soldering these components, automatic BGA machines in India have emerged as a crucial tool for modern electronics manufacturing.

This blog explores the importance of automatic BGA machines in India, their functionality, advantages, and why they are becoming indispensable in electronics manufacturing.

What is a BGA?

Before diving into the benefits of automatic BGA machines, it's essential to understand what a Ball Grid Array (BGA) is. A BGA is a type of surface-mount packaging used for integrated circuits. Unlike traditional leaded packages, BGAs use a grid of tiny solder balls on the underside of the component to make electrical connections. This design allows for higher density, improved thermal performance, and more reliable connections, making BGAs ideal for applications in computers, smartphones, and other high-performance electronics.

However, soldering BGAs manually is an extremely challenging task due to the small size and the hidden placement of solder joints beneath the package. This is where automatic BGA machines in India come into play.

What is an Automatic BGA Machine?

An automatic BGA machine is a specialized piece of equipment designed to automate the placement, soldering, and inspection of BGA components on printed circuit boards (PCBs). These machines are equipped with advanced vision systems, precise robotic arms, and reflow soldering technology to ensure that BGA components are accurately placed and securely soldered.

The automatic BGA machines in India are now widely adopted across electronics manufacturing industries, as they enhance production efficiency and ensure high-quality, defect-free assembly.

Key Features of Automatic BGA Machines

High Precision Placement Automatic BGA machines use advanced vision systems to accurately align and place BGA components on the PCB. This precision is crucial because even slight misalignment can lead to soldering defects, such as cold solder joints or bridging.

Reflow Soldering Capability Most BGA machines feature reflow soldering ovens that evenly heat the PCB and the BGA component. This ensures that the solder balls melt uniformly, creating strong electrical connections between the component and the board.

Automated Optical Inspection (AOI) To ensure that all solder joints are properly formed, many automatic BGA machines include an automated optical inspection system. This system uses high-resolution cameras to check the quality of the solder joints and detect any defects that could affect the performance of the final product.

Flexibility in Handling Different BGA Sizes Automatic BGA machines in India are designed to handle a wide range of BGA package sizes, from small micro BGAs to larger packages used in high-performance computing. This flexibility allows manufacturers to use a single machine for various applications.

User-Friendly Interface Modern BGA machines come with intuitive software interfaces that allow operators to easily program the machine, adjust settings, and monitor the production process in real time.

Benefits of Using Automatic BGA Machines in India

1. Increased Production Efficiency

One of the most significant advantages of using automatic BGA machines is the ability to dramatically increase production efficiency. By automating the placement and soldering process, manufacturers can achieve higher throughput, reduce production times, and eliminate the bottlenecks associated with manual assembly.

2. Enhanced Accuracy and Quality

Automatic BGA machines offer superior accuracy in placing components, which is essential when working with delicate and compact BGAs. The automated process minimizes human errors, resulting in higher-quality assemblies with fewer defects. This level of precision is especially important in industries such as aerospace, automotive, and telecommunications, where reliability is paramount.

3. Reduced Labor Costs

Automation significantly reduces the need for manual labor in the assembly process. With an automatic BGA machine, a single operator can oversee multiple machines, allowing manufacturers to reduce labor costs and reallocate resources to other areas of the production process.

4. Improved Yield Rates

By ensuring consistent and accurate placement and soldering, automatic BGA machines in India help to improve yield rates. Fewer defects mean less rework and scrap, which directly impacts the overall profitability of the manufacturing process.

5. Compatibility with Advanced PCBs

As PCBs become more complex, with smaller components and higher densities, manual assembly becomes increasingly difficult. Automatic BGA machines are designed to handle these complex assemblies with ease, making them ideal for manufacturing next-generation electronics.

Applications of Automatic BGA Machines in India

The use of automatic BGA machines in India spans across various industries, including:

Consumer Electronics In the consumer electronics sector, where devices like smartphones, tablets, and laptops require compact and high-performance components, BGA packages are essential. Automatic BGA machines ensure that these components are placed and soldered with the utmost precision, contributing to the performance and reliability of the final product.

Automotive Electronics The automotive industry relies heavily on advanced electronics for critical systems such as engine control units (ECUs), infotainment systems, and safety features. With the rise of autonomous and electric vehicles, the demand for reliable and high-quality electronics has never been greater. Automatic BGA machines play a key role in assembling these components to meet stringent quality standards.

Telecommunications Telecommunication equipment, such as base stations, routers, and network switches, relies on high-performance BGAs to handle data transmission and processing. Automatic BGA machines help ensure the quality and reliability of these critical components, which are essential for maintaining network performance.

Medical Devices In the medical device industry, where precision and reliability are of utmost importance, automatic BGA machines are used to assemble components for diagnostic equipment, monitoring devices, and medical imaging systems. These machines help manufacturers meet the high standards required for medical-grade electronics.

Aerospace and Defense The aerospace and defense industries require electronics that can withstand extreme conditions and deliver reliable performance. Automatic BGA machines are used to assemble mission-critical components for applications such as avionics, communication systems, and radar equipment.

Why Choose Ascompinc for Automatic BGA Machines in India?

Ascompinc is a leading provider of automatic BGA machines in India, offering cutting-edge solutions that meet the needs of modern electronics manufacturers. Here's why you should consider Ascompinc for your BGA machine requirements:

High-Quality Products At Ascompinc, we offer a range of automatic BGA machines that are built to deliver precision, efficiency, and reliability. Our machines are designed to handle the most demanding manufacturing environments, ensuring consistent performance.

Technical Support We provide comprehensive technical support to help you select the right machine for your specific application. Our team of experts is available to assist with installation, training, and ongoing maintenance, ensuring that your equipment operates at peak performance.

Competitive Pricing Ascompinc offers competitive pricing on all our automatic BGA machines, making advanced electronics manufacturing accessible to businesses of all sizes.

Customized Solutions We understand that every manufacturing process is unique, which is why we offer customized solutions to meet your specific requirements. Whether you need a machine for high-volume production or specialized applications, we can tailor our products to suit your needs.

#madeinindia#electronicsmanufacturing#margot robbie#BGAMachinesIndia#ElectronicsManufacturing#SMTTechnology#AutomaticBGA

0 notes

Text

PCB cleaning chemicals

Enhancing Electronics Manufacturing Efficiency with Advanced Equipment

In the realm of electronics manufacturing, precision and cleanliness are paramount. Circuit boards (PCBs) are the backbone of electronic devices, and any contaminants or flaws in their assembly can lead to malfunctions or even failure of the entire system. As technology advances, so does the demand for more sophisticated equipment to ensure the quality and reliability of electronic components. This has led to the development of specialized machines and tools such as PCB cleaning machines, acrylic conformal coating systems, adhesive dispensers, robotic dispensers, and electric screwdrivers, all of which play critical roles in streamlining the manufacturing process and enhancing product performance.

PCB Cleaning Machines:

PCB cleaning machines are indispensable in the electronics manufacturing industry. These machines use various techniques such as aqueous cleaning, ultrasonic cleaning, and vapor phase cleaning to remove contaminants such as flux residues, solder pastes, and other impurities from PCBs. By ensuring the cleanliness of PCBs, these machines contribute to the reliability and longevity of electronic devices.

PCB Cleaners in Delhi:

Delhi, being a hub for electronics manufacturing, offers a wide range of PCB cleaning solutions tailored to the diverse needs of manufacturers. Whether it's batch cleaning for high-volume production or precision cleaning for delicate components, PCB cleaners in Delhi provide efficient and cost-effective solutions to ensure the quality of electronic assemblies.

Acrylic Conformal Coating:

Acrylic conformal coating is applied to PCBs to protect them from environmental factors such as moisture, dust, and chemical contaminants. This thin layer of protective coating enhances the insulation properties of the PCB, prevents corrosion, and improves the overall reliability of electronic assemblies, especially in harsh operating environments.

Adhesive Dispensing:

Adhesive dispensing systems are used to precisely apply adhesives, sealants, and coatings onto electronic components and assemblies. These systems come in various configurations, including manual, semi-automatic, and fully automated, allowing manufacturers to choose the most suitable option based on their production requirements and budget constraints.

Robotic Dispensers:

Robotic dispensers offer unparalleled accuracy and consistency in adhesive application. Equipped with advanced robotic arms and programmable controllers, these dispensers can precisely dispense adhesives onto complex PCB layouts with minimal wastage. Robotic dispensers not only improve productivity but also ensure uniformity in adhesive distribution, resulting in higher quality electronic assemblies.

Dispensing Caps:

Dispensing caps are essential accessories for adhesive dispensing systems, enabling controlled and precise application of adhesives onto small and intricate components. These caps come in various sizes and shapes to accommodate different dispensing needs, ensuring optimal performance and efficiency in electronics manufacturing processes.

Fluid Dispensing System:

Fluid dispensing systems are versatile tools used for dispensing a wide range of fluids, including adhesives, lubricants, and solvents. These systems feature programmable controls and adjustable dispensing parameters, allowing manufacturers to tailor the dispensing process to meet specific application requirements. From simple dot dispensing to complex pattern dispensing, fluid dispensing systems offer flexibility and precision in electronic assembly processes.

Best Electric Screwdrivers:

Electric screwdrivers are indispensable tools for assembling PCBs and electronic components. With their adjustable torque settings, quick-change bits, and ergonomic designs, electric screwdrivers streamline the assembly process while ensuring consistent and reliable fastening of screws. The best electric screwdrivers combine performance, durability, and affordability, making them essential investments for electronics manufacturers.

Conclusion:

In the fast-paced world of electronics manufacturing, efficiency and precision are key to staying competitive. Specialized equipment such as PCB cleaning machines, acrylic conformal coating systems, adhesive dispensers, robotic dispensers, and electric screwdrivers play crucial roles in optimizing production processes and ensuring the quality and reliability of electronic assemblies. By investing in advanced equipment and technologies, manufacturers can meet the growing demands of the industry while maintaining high standards of product excellence. Visit here - https://mectronics.in

0 notes

Text

Automatic Solder Feeder

AC Solder feeder for automatic soldering machine / soldering robots, dotted type solder feed, suitable solder wire ∅0.5~∅1.2mm

0 notes

Text

Global Machine Vision Market Research and Analysis by Expert: Cost Structures, Growth rate, Market Statistics and Forecasts to 2030

Global Machine Vision Market Size, Share, Trend, Growth and Global Opportunity Analysis and Industry Forecast, 2023-2030.

Overview

The Global Machine Vision Market is likely to exhibit steady growth over the forecast period, according to the latest report on Qualiket Research.

Global Machine Vision Market was valued at USD 14.4 billion in 2022 and is slated to reach USD 27.86 billion by 2030 at a CAGR of 8.60% from 2023-2030.

Machine vision (MV) is a field of computer science that focuses on providing imaging-based automatic inspection and analysis for a variety of industrial applications, including process control, robot guiding, and automatic inspection.

Key Players:

Allied Vision Technologies GmbH

Basler AG, Cognex Corporation

Keyence Corporation

LMI Technologies, Inc.

Microscan Systems, Inc.

National Instruments Corporation

OMRON Corporation

Sick AG

Tordivel AS.

Request A Free Sample: https://qualiketresearch.com/request-sample/Global-Machine-Vision-Market/request-sample

Market Segmentation

Global Machine Vision Market is segmented into By Type, Component, Function Module, Platform, Camera Vision & Lenses and Industry. By Type such as 1D Vision Systems, 2D Vision Systems, Area Scan, Line Scan, 3D Vision Systems. By Components such as Hardware, Software, Services. By Function Module such as Positioning/, Guidance/ Location, Identification, Inspection and Verification, Gauging/ Measurement, Soldering and Welding, Material Handling, Assembling and Disassembling, Painting and Dispensing, Others) By Platform such as PC Based, Camera Based Vision System. By Camera Vision and Lenses such as Lens, Telecentric Lenses, Macro and Fixed Focal Lenses, 360-degree view lenses, Infrared & UV lenses, Short Wave Infrared Lenses, Medium Wave Infrared Lenses, Long Wave Infrared Lenses, Ultraviolet Lenses, Camera Vision, Area Scan Camera, Line Scan Cameras). By Industry such as Industrial Applications, Automotive, Electronics Manufacturing, Food & Beverage Manufacturing, Packaging, Semiconductors, Pharmaceuticals, Warehouse & Logistics, Wood & Paper, Textiles, Glass, Rubber & Plastic, Non-Industrial Applications, Printing, Sports & Entertainment.

Regional Analysis

Global Machine Vision Market is segmented into five regions Americas, Europe, Asia-Pacific, and the Middle East & Africa. A high number of providers with local roots are present in North America, which has the greatest market for machine vision because of the region's early adoption of manufacturing automation. Its supremacy in this market is also a result of the semiconductor sector's dominance in the North American region, a crucial sector for MV systems. Europe is the second-largest market for machine vision, thanks to a robust industrial sector and rising automation demand. Some of the top machine vision manufacturers and suppliers are based in this area.

About Us:

QualiKet Research is a leading Market Research and Competitive Intelligence partner helping leaders across the world to develop robust strategy and stay ahead for evolution by providing actionable insights about ever changing market scenario, competition and customers.

QualiKet Research is dedicated to enhancing the ability of faster decision making by providing timely and scalable intelligence.

QualiKet Research strive hard to simplify strategic decisions enabling you to make right choice. We use different intelligence tools to come up with evidence that showcases the threats and opportunities which helps our clients outperform their competition. Our experts provide deep insights which is not available publicly that enables you to take bold steps.

Contact Us:

6060 N Central Expy #500 TX 75204, U.S.A

+1 214 660 5449

1201, City Avenue, Shankar Kalat Nagar,

Wakad, Pune 411057, Maharashtra, India

+91 9284752585

Sharjah Media City , Al Messaned, Sharjah, UAE.

+91 9284752585

0 notes

Text

IoT based smart utility controllers

Are the utilities in your factory optimally used? Make sure you’re using the right controllers and sensors for the job!

Utilities contribute significantly to the recurring expenses in a factory, but often are not used properly. Utility controllers can be used to detect usage, and using IoT, they can help factories not only make huge savings on expenses but also predict any equipment malfunctions.

Utility controllers are generally based on sensors. Micro-Electro-Mechanical System (MEMS)-based sensors have come a long way since their invention and first use in the mid-twentieth century to evolve into the Nano-Electro-Mechanical System (NEMS)-based sensors of today. Besides, event-driven and time-driven controllers also play an important role.

Utility Controllers

HVAC usage controllers

Pressure sensors on the doors and windows can detect the open condition of doors along with the time and location, leading to reduced efficiency of the HVAC equipment and spiralling energy bills.

Humidity sensors and Air Quality sensors help in proper usage of existing HVAC equipment to the optimum temperature. In the electronics industry, they help reduce obnoxious fumes from soldering machines and flux. These sensors help maintain employee well-being.

Air repair mechanic using measuring equipment for filling industrial factory air conditioners and checking maintenance outdoor air compressor unit.

Water usage controllers

Motion detection controllers are used in automated sinks, faucets, toilet flushers and hand dryers to minimise water wastage.

Water Quality sensors ensure appropriate use of water for consumption or other activities.

Current usage controllers

Idling equipment need to be switched off to ensure reduced power bills. Current monitoring sensors can also indicate malfunctioning equipment for appropriate action.

Access Controllers

Access to factory premises is controlled by access controllers. Within the factory too, only restricted people are allowed in certain zones requiring RFID-based or similar entry.

IR Sensing controllers

These are the most common types of sensors which find use in a variety of applications such as remote controls, breath analysis, infrared vision to visualise heat leaks in electronics and non-contact-based temperature measurements. They are of high utility value to many IoT projects in the healthcare industry.

Smoke and Fire Detection controllers

3d rendering smoke detector on ceiling

Smoke detectors within a work area can warn of potential malfunctioning of any equipment or impending danger in the form of fire incidence. Fire detectors perform a similar role, thwarting any fire hazard from happening.

Imaging and Optical sensors

Image sensors find their use in multiple ways. They are implemented to improve security systems in the premises and to control access.

Robotic Sensors

More and more factories today are using robotics. The robots and cobots use many sensors such as gyroscope sensors, accelerometer sensors, collision detection sensors and the associated End of Arm Tooling (EOAT) uses various pressure and magnetic sensors. These sensors ensure proper functioning of robotics.

Other sensors

Besides, industry-specific sensors are used in specialised industries such as liquid processing, petrochemical and mining.

Event-driven and time-driven controllers

Many controllers are activated at specific times of the day triggering, for example, lights to be turned on after 6PM and turned off after 6AM, thus saving on energy consumption.

Some events trigger the activation of controls to perform specific tasks, for example, in the event of an untoward power fluctuation the equipment is turned off automatically, protecting it from being damaged and avoiding the repair costs.

Automated Guided Vehicles (AGVs), Cobots and moving utility vehicles stop when they near any obstruction in the form of material or humans in a collaborative environment.

Smart Controllers

All the above types of controllers detect variation in other forms of energy and share the information in digital signals. This information is captured in real-time by data loggers and presented in a meaningful format which is used for appropriate decisions. IoT based gateway-less communication between equipment or through the cloud result in better planning and production.

Profitability of a factory is improved by reducing wastage on unused resources. Many direct benefits accrue such as the performance analysis of equipment. When an equipment is found to generate more heat or is vibrating more than is normal, it may be an indication of machine wear and tear and calls for maintenance. Many faults are detected by these sensors in real-time, much ahead of any potential damage to equipment leading to costly repairs on equipment in addition to easily avoidable downtime. Many hidden defects are detected which can be potentially hazardous to employee well-being, such as water and air quality.

Overall Equipment Efficiency (OEE) can be improved by analysing the different manufacturing/processing lines within a factory, e.g. the body shop is producing the desired results but the paint shop calls for closer scrutiny of the paint shop or any specific equipment within it. Similarly, for a factory in multiple locations, any non-performing equipment in a location may be moved to another where it can be better utilised.

The analysis of information over a period of time helps factories to plan into the future for better productivity, quality and profitability.

The Industrial IoT Solutions India from MELSS offers comprehensive IoT solutions including hardware, firmware and software. We deliver solutions for both on-premise and cloud-based implementation.

0 notes

Text

Linear Motion Products for Automation

Automation is a market where industrial linear motion products are used in large numbers. You can find CSK products in the smallest most simple machine to the largest and most complex system imaginable. In short, wherever there is a need in a machine to push, pull, lift, tilt, turn or move something CSK has a suitable product. Typical areas include:

Robots and manipulators

Pressing, cutting and gluing

Printing and scanning

Packaging, palletizing and dispensing

Welding, soldering and drilling

Automatic warehouses

Measuring and supervision

Assembly

Linear Motion Robotics

CSK's linear motion automation products play a vital role in factory automation, enabling precise and controlled linear motion in various applications. They optimize factory automation systems by offering advantages such as high precision, smooth operation, reliability, and compact design. Here is an all-round interpretation of the application of CSK's linear motion products in factory automation:

1. Robotic Systems:

- Linear Guides: Linear guides are extensively used in robotic systems to facilitate smooth and accurate linear motion for robot arms, gantries, and other moving components. CSK's linear guides ensure precise positioning, stability, and repeatability, enhancing the overall performance and productivity of robotic systems.

- Ball Screws: Ball screws convert rotary motion into linear motion and are employed in robot actuators for precise and controlled movement. CSK's ball screws offer high precision, low backlash, and efficient power transmission, contributing to accurate and reliable robotic operations.

2. Material Handling and Conveying:

- Linear Motion Systems: Linear motion systems, including linear guides, ball screws, and linear actuators, are utilized in material handling and conveying systems. CSK's linear motion products enable smooth and efficient linear motion for conveyors, lifting mechanisms, and transfer systems, optimizing the movement of materials within the factory.

CSK's linear motion systems provide high load capacity, low friction, and precise positioning, ensuring reliable and efficient material handling. They contribute to increased throughput, reduced downtime, and improved overall productivity in factory automation.

3. Assembly and Testing Equipment:

- Linear Actuators: Linear actuators, such as electric cylinders or linear stages, are used in assembly and testing equipment for precise positioning, pushing, or pressing components during the manufacturing process. CSK's linear actuators offer accurate and controlled linear motion, ensuring precise alignment, reliable testing, and consistent assembly quality.

- Linear Bearings: Linear bearings are employed in assembly and testing equipment to support and guide the movement of components or testing probes. CSK's linear bearings provide smooth and low-friction linear motion, contributing to the accuracy and repeatability of assembly and testing processes.

4. Packaging and Labeling Machines:

- Linear Motion Systems: Linear motion systems, including linear guides and ball screws, are employed in packaging and labeling machines for precise and controlled linear motion. CSK's linear motion products enable accurate positioning of packaging materials, products, or labeling mechanisms, ensuring precise and efficient packaging processes.

CSK's linear motion drive systems offer high positioning accuracy, smooth operation, and high-speed capabilities, enhancing the productivity and accuracy of packaging and labeling machines. They contribute to reduced errors, improved packaging quality, and increased production throughput.

0 notes

Text

Top Trends in PCB Assembly for 2025

Top Trends in PCB Assembly for 2025

PCBs are the heart of the modern world. Whether it's household equipment, industrial equipment, or defense ordnance, printed circuit boards are running everything. With new developments, the global scene of PCB manufacturing is changing rapidly. Using the newest technologies is not only a great concept, but staying competitive depends on it as well. From downsizing to AI-driven manufacturing, 2025 promises to bring major breakthroughs along with making advancements in current technologies that will change the way Printed Circuit Boards (PCBs) are manufactured.

This article will walk you through some key industry trends that will sketch the future of PCB assembly.

5 Key Trends in PCB Assembly to Follow in 2025

As the world is moving towards manufacturing more complex products and adopting advanced technologies, the PCB assembly industry is also observing several key trends. Here are a few noteworthy trends to follow.

1. Shrinking is in High-Density Interconnections: HDI and Miniaturization

Think about our daily gadgets, such as wearables, Internet of Things devices, and sophisticated medical electronics. These devices need robust and small PCBs, and therefore, in these spaces, High-Density Interconnect (HDI) technology excels. HDI lets electronic gadgets be more powerful despite their compact stature. In what manner? For high-speed applications, it increases signal integrity, lowers component spacing, and permits smaller trace lengths, hence enhancing electrical performance. And it will change the entire PCB manufacturing market.

According to a forecast [1], the HDI PCB market is expected to rise rapidly and, by 2032, will reach almost $40 billion. That makes the direction in which things are heading quite obvious.

2. Smart Factories: Artificial Intelligence and Automation

Like in every other industry, PCB assembly is becoming significantly faster, smarter, and more efficient. Industry 4.0 and manufacturing driven by artificial intelligence lead the push. Think about robotic soldering and pick-and-place robots for fast, more perfect component installation. Artificial intelligence and machine learning have found their way into quality control, that is, for error reduction and flaw detection done automatically. Imagine the Internet of Things, connected production lines, allowing real-time monitoring and predictive maintenance.

3. Bendable and Adaptable: Rigid-flexible PCBs

Flexible and rigid-flex printed circuit boards are becoming more popular in industries such as transportation, aircraft, and healthcare electronics. But you may think, why so? Because of their small size and lightweight nature, they are ideal for manufacturing small, portable electronic devices. They can withstand significant external force and resist bending and vibration. They endure longer with fewer interconnect failures, making them more reliable.

4. Green is Good: Manufacturing Sustainable Circuit Boards

Growing worries about e-waste and carbon footprints force sustainability to the front stage in PCB production. Lead-free soldering, biodegradable and reusable substrates, recyclable materials, and energy-efficient manufacturing procedures will become the focal points in the near future. It's about matching global laws and customer demand as much as it is about environmental responsibility.

5. Printing the Future: 3D Printing in PCB Assembly

Additive manufacturing is revolutionizing PCB manufacturing and streamlining complex multilayer design construction. From this, faster prototyping, reduced material waste, and more customization for specific uses follow. This is a breakthrough for design and development; it will only get more so.

The Final Thought

There are a lot of exciting new possibilities in the PCB assemblyand PCB manufacturing industries. Miniaturization, automation, sustainability, and developments in AI-driven manufacturing will enable you to produce premium printed circuit boards (PCRs) that satisfy future electronics needs. Survival in a dynamic industry depends on keeping ahead of the competitors. By following these trends and wise technology investments, you could set yourself up for success in 2025 and beyond.

Know More: https://www.pcbpower.us/blog/top-trends-pcb-assembly

0 notes

Text

SMT Equipment Market Expectation Surges with Rising Demand and Changing Trends

Latest study released by AMA Research on Global SMT Equipment Market research focuses on latest market trend, opportunities and various future aspects so you can get a variety of ways to maximize your profits. SMT Equipment Market predicted until 2027*. Surface mount technology (SMT) Equipment possesses high component density (components per unit area) and can have many more connections per component. These equipment’s size is much smaller than the through-hole component because it may have very fine pitched and smaller leads or may contain no leads. They are widely used for placing capacitor, resistor, inductor, and other components on Printed Circuit Board (PCB’s). The growing demand for SMT equipment in the consumer electronics industry is driving the market growth. Some of Key Players included in SMT Equipment Market are

Fuji Corporation (Japan)

Hitachi High-Technologies Corporation (Japan)

Mycronic (Sweden)

Nordson Corporation (United States)

Panasonic Corporation (Japan)

JUTZE Intelligence Technology Co.,Ltd. (China)

Cyber Optics Corporation (United States)

Electro Scientific Industries, Inc. (United States)

Juki Corporation (Japan)

Hangzhou Neoden Technology Co.,Ltd (China)

KLA Corporation (United States)

Mirtec Corporation (United States)

OMRON Corporation (Japan)

Universal Instruments Corporation (United States)

Europlacer (United States)

Evest Corporation (Taiwan)

Market Trends: Progression in Self-Driven Cars

Growth in Medical Technology

Drivers: Rising Number of Electric Vehicles

Increasing Number of Wearable Devices

Growing Demand for Miniature Electric Circuits and Components

Challenges: Lack of Trained Labor

Opportunities: Growth in Smartphone Penetration

Emerging Industrial Robotics

The titled segments and Market Data are Break Down by Type (Automatic SMT Equipment, Semi-automatic SMT Equipment), Application (Consumer Electronics, Industrial, Medical, Automotive, Telecommunication, Aerospace & Defense, Telecommunications Equipment, Energy & Power Systems), Equipment Type (Inspection Equipment, -Laser/SPI, -X-Ray/AXI, -Optical/AOI, Placement Equipment, Soldering Equipment, -Wave Oven, -Reflow Oven, Screen Printing Equipment, Cleaning Equipment, Repair & Rework Equipment)

Presented By

AMA Research & Media LLP

0 notes

Photo

Automatic soldering Robot - Without the proper machinery, you will not be able to manage a full- fledged production line. If you are looking to upgrade your production line then we at 1clicksmt-solderingrobot.com can definitely help you with the perfect equipment. Now upgrade your production line with products like I-352 Inline Automatic Soldering robot, H351 Automatic Soldering Robot and many more. To get more related information, just visit the link or give us a call at +86-13537273006

0 notes

Text

Choosing a Torque Meter

A torque meter is a device that measures the amount of force needed to turn a machine. This device measures torque in metric units, which can range from 32.5 to 810 Nm. When choosing a torque meter, you must consider its mounting options. You need to determine whether it will be mounted on a flange or on a shaft. The mounting style should be square or hex, and the meter must be compatible with both clockwise and counterclockwise rotational motion. It must also be certified for NIST traceability.

The rotary type is often used in automotive applications, where it is commonly known as a dynamometer. This type of torque sensor is useful for estimating motor efficiency, performing torsional and rotational vibration studies, and more. Strain gauges are also commonly used in the measurement of torque. The sensors are mounted on the drive shaft, and a wireless interface powers them and transmits the data to a nearby processing unit. A data acquisition (DAQ) system is also available to record and store data.

A torque tester is an important component of a dynamometer, and provides both torque measurements and angular speed (RPM). The angular speed of a rotating machine allows engineers to accurately calculate engine and motor performance. Some torque meters are even able to measure static torque, with an in-line rotary sensor. You can also use a reaction torque transducer to measure the torque in a static situation.

torque meter are available in handheld and tabletop versions. Handheld versions are ideal for automotive use, while tabletop models are better suited for lab applications. Many torque meters have RS-232 ports to save and compare measured torque values. For long-term measurements, an interface and software are invaluable. You can even use a printer to record measurements. So, there are a lot of different uses for a torque meter.

A self-contained electronic torque and angle meter pro is another option. This tool converts any wrench into a precision torque instrument with the help of its rotatably-platform. It features three-colored indicators, an audible signal, and a tactile vibration alert. Unlike a standard torque meter, this digital torque meter offers a convenient design for use in critical industrial applications. This device is designed to measure torque with the aid of a square drive extension, eliminating the problem of hand-hold position error.

Reaction torque tester use a special strain-gauge sensor called a "reaction torsion" that is attached to a metal body. The sensor is mounted in between two metal flanges, one fixed to the ground or a rigid structural member, and the other fixed to the rotating shaft. The rotation generates shear forces between the two flanges, which are captured by foil strain gauges attached to sensor beams. The strain-gauge is then converted into an electrical current via a Wheatstone bridge.

Modern torque meter have a digital display that measures the output signal from the transducer. The display converts the reading into the torque value. This technology usually is located within the housing of a desktop torque tester. A portable display may be used in conjunction with an external rotary transducer. Moreover, a handheld torque analyzer can be used with a rotary or stationary transducer. There are many different types of torque testers to suit different types of work.

#electric screwdriver#pneumatic screwdriver#screw assembly robot#screw assembly solutions#screw tightening robot#automatic screwdriver#benchtop ionizers#dispensing machine#dispensing robot#automatic dispenser#epoxy dispensers#fan ionizer#glue dispensing machine#ion bar#ion gun#led magnifier#static charge eliminators#torque meter#torque tester#automatic soldering machine#robotic soldering machine#soldering fume absorber#soldering fume extractor#soldering robot#soldering station#temperature controlled soldering iron

0 notes

Text

ULiROBOTS PCB circuit board automatic soldering robot

Automatic soldering robot is a kind of welding equipment. The soldering system is the core part of the welding robot. The soldering tin system is mainly composed of automatic tin feeding mechanism, temperature control, heating element and soldering iron tip. The robot arm can be adjusted to any required welding position, and the tin wire will automatically extend to the soldering iron with a fixed speed and a fixed amount; the digital temperature is set at a glance, light and flexible, does not occupy space, temperature, tin feeding speed, and tin point size Adjustable.

1. Using ABB six-axis robotic arm

2. With visual positioning system

3. The real unmanned operation can be directly connected to the previous process assembly line.

4. According to different welding needs, it can be arbitrarily matched with the front section, the middle section and the end section to adapt to more products!

5. The appearance of the machine is novel, and the main body adopts a special surface treatment, which is beautiful and generous.

6. The new lean design, the same size brings a larger effective stroke.

7. The user software developed based on the Windows operating system is more in line with the user's operating habits.

8. The real digital program, modify the parameters and input directly, the same type of tin point can be changed once, and the insertion point can be deleted by one key operation;

9. The 12-inch high-definition touch screen man-machine interface and the dynamic display of the running track make your welding process more intuitive.

10. The tin feeding can be started at any time, which fully meets the various soldering processes and improves machine efficiency.

11. Comes with an anti-collision function, which reduces the damage rate of the machine and products in the event of an accidental collision (optional function).

12. The authority management mode prevents the operator from modifying the parameters by mistake.

13. The parameters of the solder joint types can be switched flexibly, and the running speed of the solder joints can be set independently without affecting each other.

14. With functions such as height correction and Z, the angular deviation generated after the repositioning of the mold can be corrected.

15. The compensation point is automatically calculated, and the angle compensation and the center compensation can be switched at will.

16. Four different types of array methods directly shorten the running distance and improve production efficiency.

17. The file name can be freely created, copied, modified, deleted and supports Chinese/English, numbers, and symbols input.

Features:

1. Flexible movement, low movement inertia, and strong versatility;

2. Compact size and small footprint;

3. Independent research and development of special solder control system based on industrial computer;

4.8-inch high-definition touch screen man-machine interface, dynamic display of running track;

5. Authority management mode to prevent the operator from modifying the operating parameters by mistake;

6. Flexible soldering methods, with multiple functions such as spot welding and drag welding;

0 notes